Water Demineralization by Ion Exchange

Water Demineralization by Ion Exchange

14 Oct 2025 | Water Treatment & Industrial Processes

Softening alone is insufficient for high-pressure boiler feed waters and many process streams, especially in electronics manufacturing. In addition to removing hardness, these processes require the elimination of all dissolved solids, such as sodium, silica, alkalinity, and mineral anions (Cl^-, SO_4^{2-}, NO_3^-). This is where demineralization by ion exchange becomes essential.

What is Demineralization?

An Ion Exchange Demineralization Plant (IX Demin Plant) is a critical component in industrial and commercial operations, removing impurities and minerals from water through ion exchange. This process produces high-quality deionized or demineralized water, vital for ensuring the integrity and reliability of end products across various applications.

Short: Demin Water

Processes Involved in Demineralization

Cation Exchange

The cation exchange resin bed contains strong acid cation exchanger in hydrogen form, converting all salts in feed water into acids. Alkaline salts form carbonic acid (H_2CO_3), while neutral salts form mineral acids (HCl, H_2SO_4, HNO_3).

Service Cycle Reactions:

- 2R–SO_3H + Ca(HCO_3)_2 \rightarrow R_2–Ca + 2H_2CO_3

- 2R–SO_3H + Mg(HCO_3)_2 \rightarrow R_2–Mg + 2H_2CO_3

Notes: Outlet water is acidic (pH ~2–3), and sodium/hardness leakage is determined.

Anion Exchange

The anion exchange resin bed, in hydroxyl form, neutralizes mineral acids from the cation unit and removes residual carbon dioxide and weakly ionized silica.

Service Cycle Reactions:

- 2R–NH_4 + SO_4^{2-} + 2H_2O \rightarrow R_2–SO_4 + 4OH^-

- R–OH + HCl \rightarrow R–Cl + H_2O

A mixed bed unit is often used post-process to further purify water, acting as a polisher.

Regeneration of Resins

Cation Exchange Regeneration

On exhaustion, the cation resin is regenerated with HCl or H_2SO_4 in co-flow or counter-current-flow mode. Counter-current mode is preferred, reducing sodium slip to less than 1 mg/L.

Anion Exchange Regeneration

On exhaustion, the anion resin is regenerated with NaOH after backwashing to remove suspended matter. Counter-current mode reduces silica slip to less than 0.2 mg/L as SiO_2.

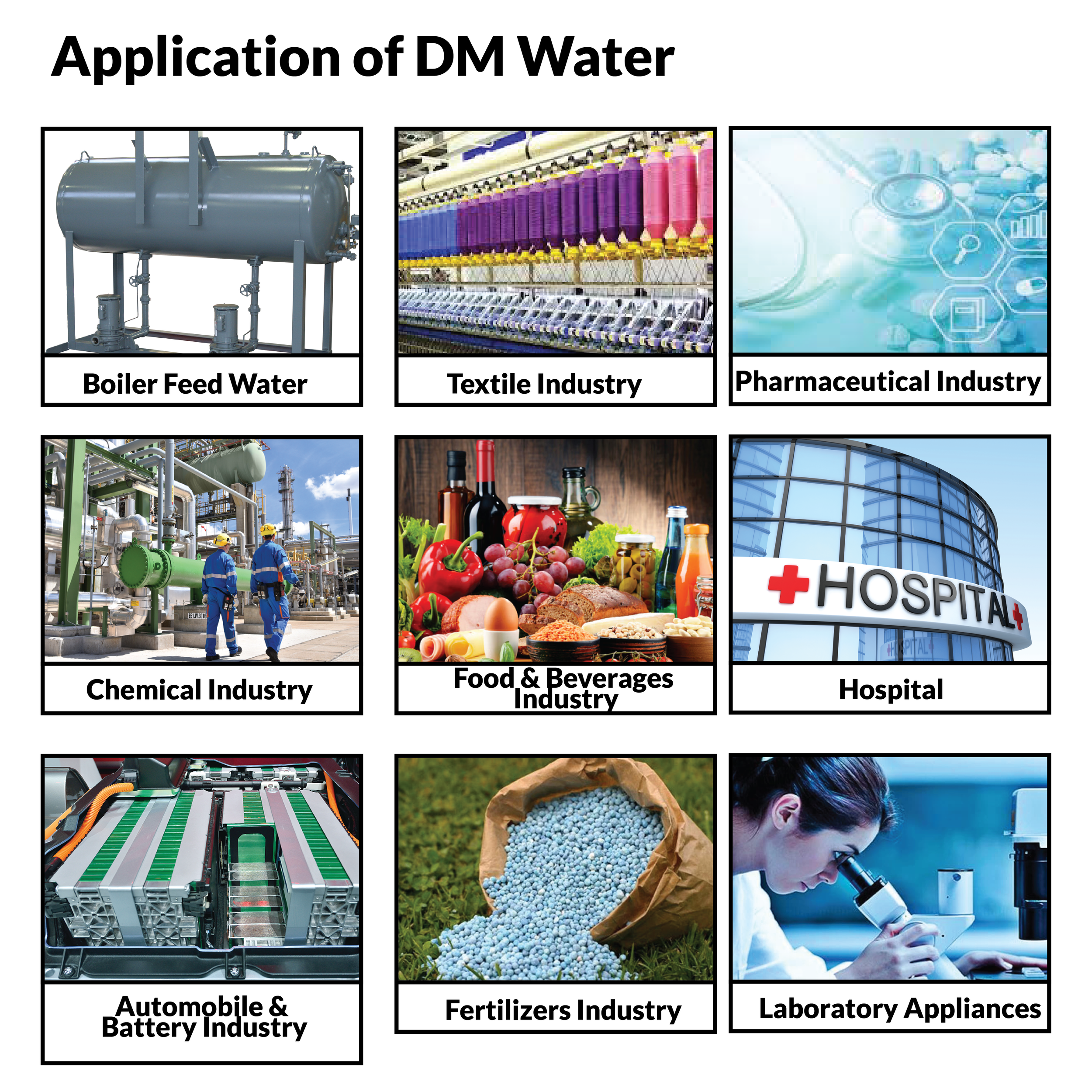

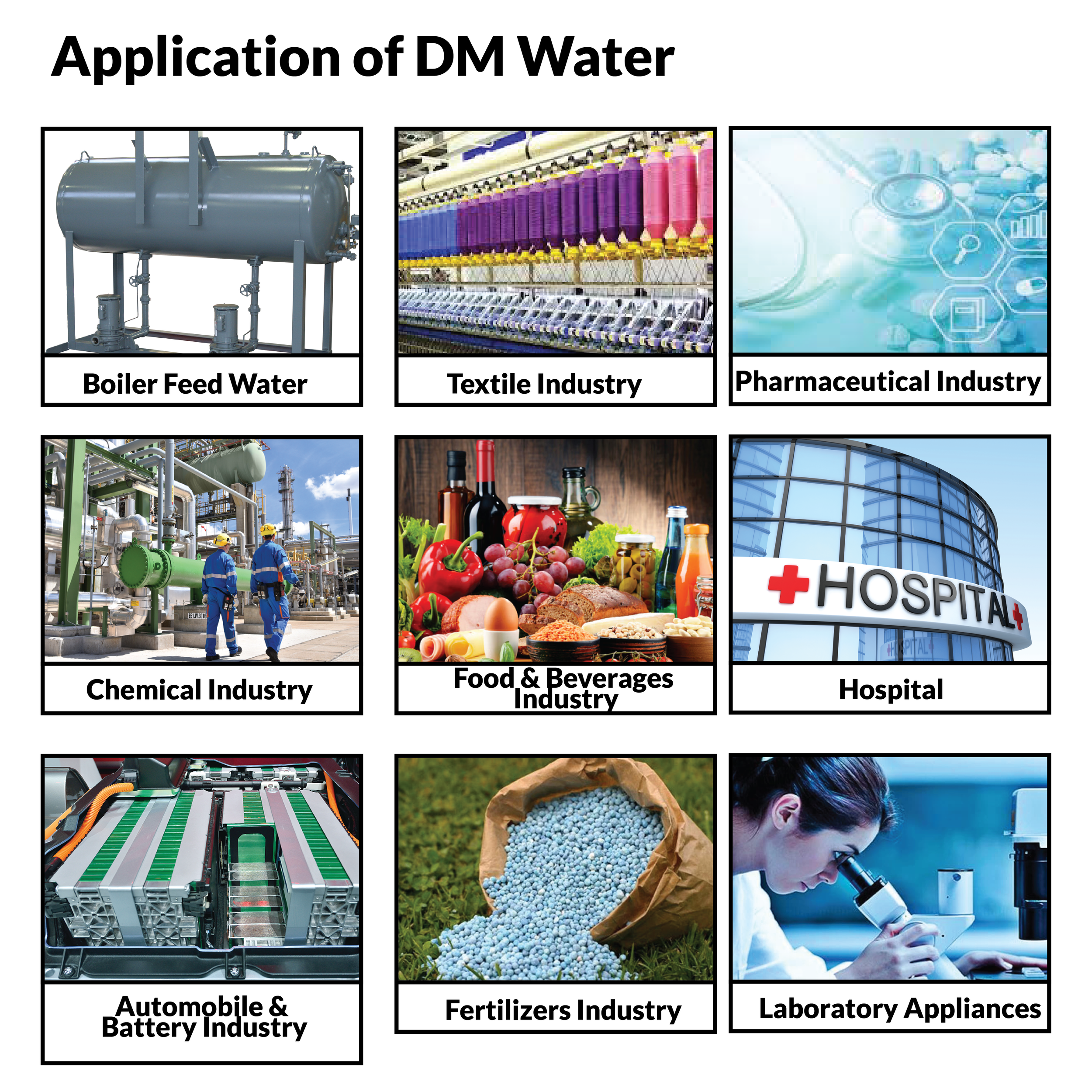

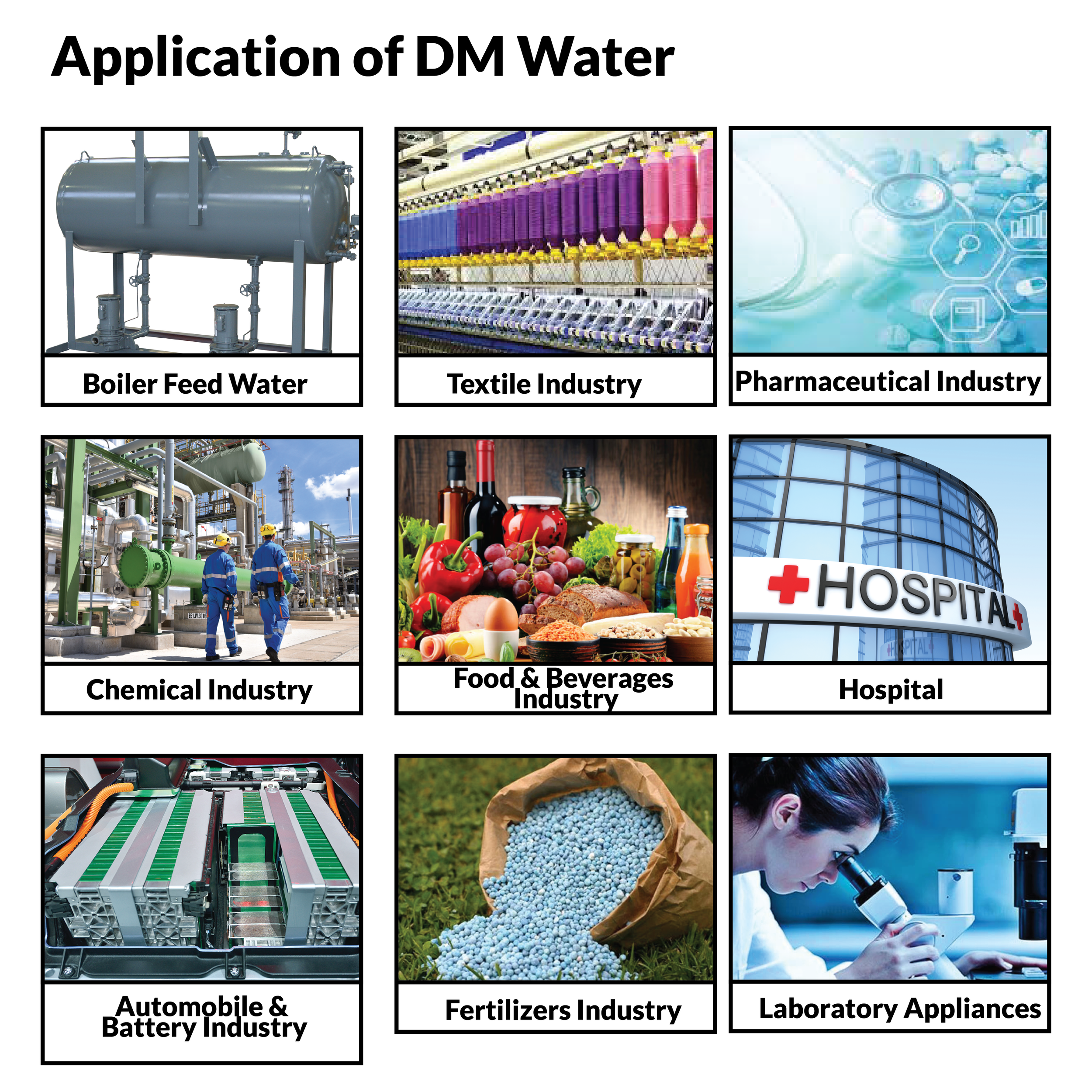

Applications of Demineralized Water

Boiler Feed Water

Ensures efficient steam generation by preventing scale and corrosion.

Pharmaceutical Industry

Provides mineral-free water for drug formulation and processing.

Chemical Industry

Used in manufacturing to prevent ionic contamination.

Textile Industry

Supports dyeing and processing with pure water.

Food & Beverage Industry

Ensures purity in food processing and beverage production.

Automobile & Battery Industry

Used in battery production and vehicle manufacturing.

Pros and Cons of Demineralization

Advantages

- Removes nearly all dissolved salts.

- High recovery when water is recycled.

- Low maintenance requirements.

- Essential for industries like pharmaceuticals, electronics, and power generation.

- Minimal downtime due to mechanical failures.

Disadvantages

- Resins can be fouled by organic load or iron.

- Waste brine disposal requires careful handling.

- High capital cost for system setup.

- Regeneration chemicals need safe handling and disposal.

- Regular replacement of resin beads adds to operational costs.