Applications of Ion Exchange Resin

Applications of Ion Exchange Resins

26 Dec 2025 | Water Treatment & Industrial Processes

Ion exchange resins are versatile materials designed to facilitate the removal or exchange of specific ions from solutions. Their applications span domestic, commercial, and industrial sectors, including chemical industries, water purification, and pharmaceutical processes, where they are critical for material separation, liquid purification, and ensuring the efficiency of various industrial processes.

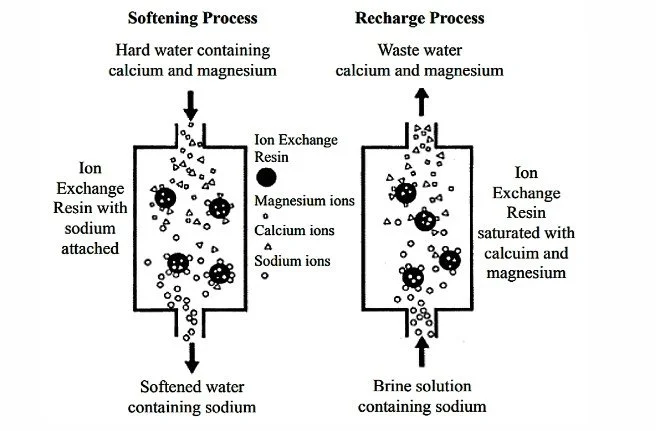

Water Softening

The ion exchange method softens water by replacing calcium (Ca^{2+}) and magnesium (Mg^{2+}) ions with sodium (Na^+) ions. This process enhances soap efficiency by reducing interference from calcium and magnesium, resulting in better lather and improved cleansing. Ion exchange significantly improves water quality for cleaning activities.

Water Demineralization

Ion exchange is used to remove all minerals from water to achieve high purity. Water is first treated with cation resins in hydrogen form to eliminate cations, followed by anion resins in hydroxyl form to remove anions. The resulting H^+ and OH^- ions combine to form water molecules, producing water with minimal sodium and silica content.

Dealkalization Process

Dealkalization reduces water alkalinity, lowering hardness and sodium content associated with alkalinity, ultimately decreasing dissolved mineral concentrations.

Key Industrial Applications

Special Ion Removal

Specialty resins, such as chelating resins, are designed for selective ion removal. Modified for exceptional thermal stability, impact resistance, and chemical resistance, they are ideal for removing metals like iron, arsenic, fluoride, barium, and strontium, and are used in processes like brine softening.

Nuclear Industry

Ion exchange resins enhance safety and efficiency in nuclear power generation by removing radioactive isotopes, purifying water, reprocessing nuclear fuel, decontaminating systems, and managing waste.

Boiler & Cooling Water

Minerals and ions in boiler and cooling water can cause scale, corrosion, and reduced performance. Ion exchange resins prevent plant downtime, costly maintenance, and equipment failure by addressing scaling, corrosion, and fouling.

Heavy Metal Removal

With rising heavy metal levels in wastewater from industries like plating and battery production, ion exchange resins effectively capture these non-biodegradable, potentially carcinogenic substances, protecting the environment and ensuring water purity.

Ultrapure Water Production

Ion exchange is critical for polishing ultrapure water in the power and semiconductor industries, removing ionic contaminants to meet stringent purity standards and combat corrosion and microbial/particle contamination.

Food & Beverage Industry

Ion exchange supports sugar production, dairy manufacturing, water purification, and enzyme purification by removing trace elements, replacing substances, isolating components, and acting as a catalyst in biochemical processes.

Additional Industry Applications

Pharmaceutical Industry

Ion exchange resins are integral in pharmaceuticals, catalyzing reactions, purifying ingredients, and acting as excipients in tablet formulations. They support taste masking, drug release, tablet disintegration, bioavailability, and chemical stability.

Chemical Industry

In the chemical industry, ion exchange resins are used for extracting heavy metals, improving surface quality, and coating, playing a key role in producing phenol, chlorine, and caustic soda.

Textile Industry

Ion exchange resins support textile processes through water treatment, chemical recovery, effluent treatment, process water purification, desalination, detergent regeneration, and color fixation.